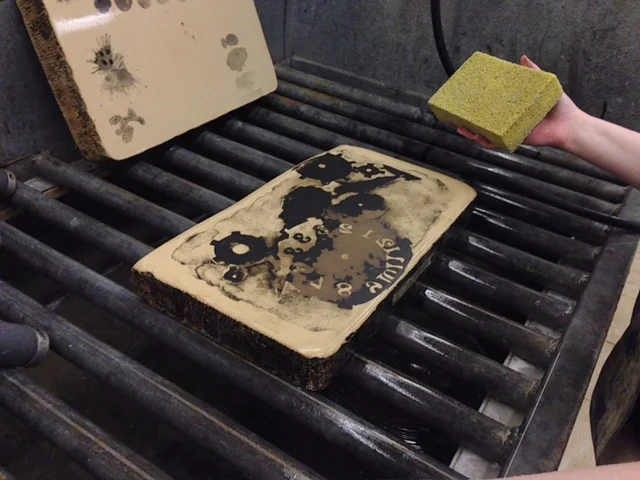

This is the stone I use to print Gears of Time. It is Bavarian limestone, one of the best limestones for lithography. The reason why lithography works is based on the principal that water and grease/oil don't mix. All of the blacks and grays on the stone were made with oily materials that will attract and hold the greasy ink while the light areas will fill with water that will reject the greasy ink.

Before I can print the stone, the protective coating on the image has to be removed with solvent and a little elbow grease.

With the coating removed, the image needs to be revived with fresh grease. After fulling covering the stone, I use a handheld fan to dry the grease.

Here I use a hose to force a water jet to remove the excess grease from the stone, leaving only the black marks coated with grease. The giant wheels to the side are used to grind old images off of lithography stones so that they can be reused. It is possible to still find stones with images from the 1800's that can be printed if they were stored properly.

The grease is starting to come off of the light areas of the piece revealing the stone.

Now that all the excess grease has been removed, the stone must be kept damp to keep the balance of water/oil.

This is the super thick ink used for lithography being laid out and put on a roller.

In between rolling on the ink, I sponge the stone to keep it damp. If any area of stone dries out, the next roll of ink will stick to the area no longer being protected by water.

Since the edges of the stone dry out faster than the middle, it is common to have some ink buildup on the sides. This must be removed before printing or it can ruin the print with messy black edges. I use a special chalk-like stick to remove the ink.

After aligning the print paper over the stone, I cover it with newsprint and the protective plastic covering. The press bar is greased so that the stone can still be moved through the press once the pressure has been set. Setting the pressure too high can actually break a stone but setting the pressure too low will result in a faint print.

After running the stone through the press, I slowly peel the print from the stone.

After careful peeling, I have a fresh print of Gears of Time. The print is set aside to dry on a rack while I prepare the stone for storage.

Once printing is done, the stone is rolled with ink a few times to help prepare the image for storage. When the stone and image are properly cared and stored for the image can be printed decades, even a century later. The print on the wall just above my head was printed by my professor when he got a stone that had a page from an old science book still on it. The image had been drawn on the stone in the mid-1800s but printed the same as the day it was first made.

Rosin and talc. It was repeated by my professor so many times, that I can't forget it. The stone is dusted with rosin that stick to the greasy ink, setting the image on the stone.

Talcum powder seals the rosin image to the stone.

Next gum arabic is poured on the stone to seal the image and the stone. I have to make sure that the entire stone face and image are covered otherwise the next time I print, there could be holes in the image.

Once the entire stone face is covered, I use cheesecloth to buff off all the excess gum arabic. After a short dry time, I put a paper cover on the stone and put it back on the shelf. When I want to print again, I start the process anew.